Automatic shot blasting is high productive, best and consistent quality shot blasting process. This is an airless type of surface preparation method which is done by using high RPM turbines and without use of any compressed air. Automatic shot blasting are designed with various types of conveyor systems. Roller conveyor, monorail/Hanger conveyor, Diablo type rollers, tire type rollers, trolley type conveyors, table type, belt conveyor, mesh conveyor etc. These conveyors are used for conveying the material IN & OUT of automatic shot blasting equipment and are specially designed for wear & tear which are manufactured in house as per the requirement job.

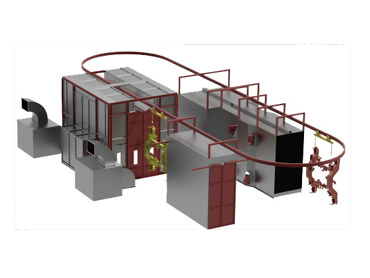

Automatic shot blasting and painting lines are one point solution for complete surface preparation and painting job. These machines are integrated with handling, pre cleaning, pretreatment, drying, shot blasting, painting & drying systems. Jon once loaded onto the conveyor will come out after completing all process of corrosion prevention. These lines are designed with roller conveyor as well as monorail conveyer system. Options can be provided for automatic or manual spray painting and can be designed as per the size of job and requirement of end user. Equipment can be supplied with various type of conveying system.

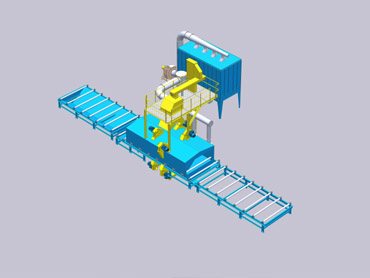

Most commonly used machine in Fabrication industry, power projects, petrochemical construction projects etc. All types of structural steel products can be shot blasted with this machine. Machines are available with opening size from 1meter x 1 meter to 3 meter x 2 meter opening size.

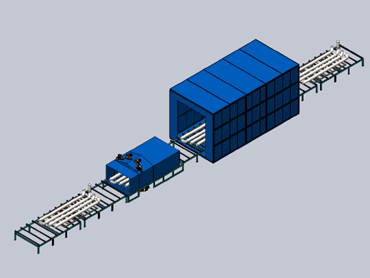

Automatic shot blasting with roller conveyors for plates, flats, bulb bars, rolled angles, channels, and other flat products. This type of machine widely used in ship building industry, storage tank projects etc. where large amount of plates are used. These machines have built in brush off and blow off system for automatic cleaning of abrasive from the job. Machines available from 1 meter to 4 meter width.

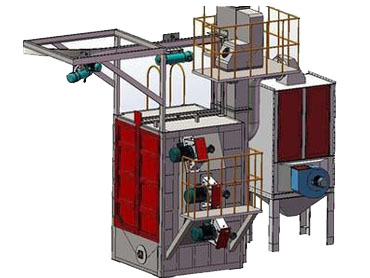

Used for various types of jobs in Automobile, casting& foundry, fabrication industry for pipe fitting in piping projects etc. Multiple jobs are loaded on the hangers at a time for shot blasting. These are high productive machine and also used for batch type production. Machines are available in various sizes and variety of jobs.

Perforated wear resistance belt and mesh type conveyor is used for small components in mass production lines. Commonly used in pavement tiles, utensils manufacturing, small component manufacturing industry. It can be designed from 500mm wide to 1.2 meter wide conveyor system

Used for various types of jobs in Automobile, casting& foundry, fabrication industry for pipe fitting in piping projects etc. Multiple jobs are loaded on the hangers at a time for shot blasting. These are high productive machine and also used for batch type production. Machines are available in various sizes and variety of jobs.

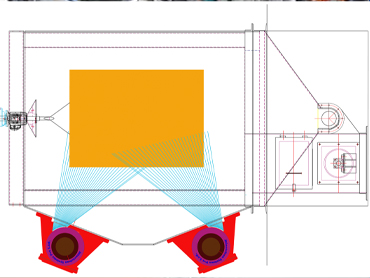

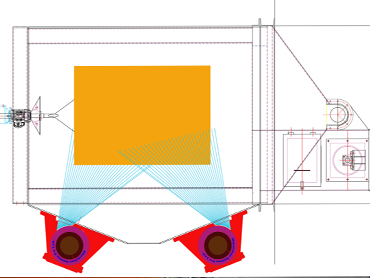

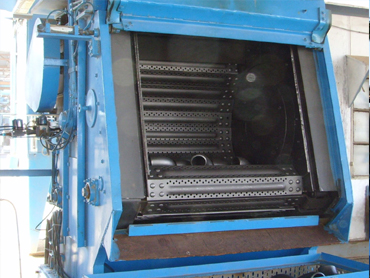

Diablo type rollers and tire type conveyor are used to convey Pipe for automatic shot blasting process. Machine can be designed for pipe ranging from 1/2 “to 60” Dia and normally supplied with Feeding, buffer stock, loading & unloading systems. Very commonly used in pipe coating industry, pipe lines projects in petroleum, power, oil & gas, petrochemicals industries. Machine can be designed of the size & design of fright container which can be used for cross country pipe line projects.

Swing table is the commonly known name for table type machine. Used by small and medium industry for various size of components. Machines are available with Table size from 1 meter diameter to 2.5 meter diameter.

Tumble blast machine with rubber belt is ideal for mass-produced parts, which can be tumbled and will perfectly meet your requirements. The blasting chamber is a compact chamber fitted with shafting and drums to accommodate the rubber belt. This equipment is integrated with recovery, cleaning & dust collection system all of these are interlocked. Machines are available from 0.5 cubic foot to 3 cubic foot.

Internal pipe blasting equipment’s are divided into air blasting equipment’s and wheel blasting equipment’s. Internal pipe blasting machine quickly and effectively removes the rust, dirt, scale, residues from inside the piping and it can also reduce the internal surface stress Machines are available in various sizes and variety of jobs.

Shot Peening is a process of stress relieving from metal. Shot peening machines can be designed with turn table type, spinner hanger type, reciprocation type etc. equipment can be both pressure blasting type & centrifugal airless type.