A company created to prevent corrosion, by a small group of highly experienced professionals in the field of surface preparation and coatings. In today’s competitive and ever demanding market, the formula for success includes effective utilisation of latest technology for best results at lowest cost and by providing expert and timely services. At Blastclean Systems we believe in this and trying to give one point solutions to all your needs of surface preparation and painting which includes from equipment design to complete operations & maintenance. Blastclean Systems have its own well experienced team of engineers who can suggest what type of equipment and process can give best results with most cost effective methods.

Automatic shot blasting is high productive, best and consistent quality shot blasting process. This is an airless type of surface preparation method which is done by using high RPM turbines and without use of any compressed air. Automatic shot blasting are designed with various types of conveyor systems. Roller conveyor, monorail/Hanger conveyor, Diablo type rollers, tire type rollers, trolley type conveyors, table type, belt conveyor, mesh conveyor etc. These conveyors are used for conveying the material IN & OUT of automatic shot blasting equipment and are specially designed for wear & tear which are manufactured in house as per the requirement job.

Semi-automatic shot blasting equipment’s are booth type machines where in the operator can walk into the booth and carry out the shot blasting as per requirement. Advantage of this system is that it can accommodate variety of jobs. This is batch type Machine where the job can be conveyed into the booth by trolley, crane, monorail, or by hand. In this machine shot blasting done manually but recovery, recycling, dust collection etc. are all automatic processes. Machine can also be designed with complete auto recovery as well as semi-automatic recovery system.

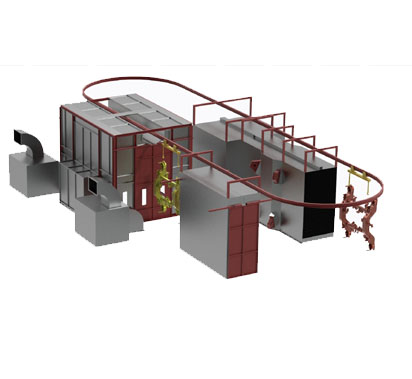

Water curtain, water scrubber, dry filter, down draft, side draft, pressurized, negative pressure are the various type of paint booths Blastclean can design, manufacture and supply of size as required by customer. Paint booth can be supplied with material handling system like trolley, roller conveyor, slat conveyor, monorail etc.

These are most commonly and widely used blasting equipment in blasting industry. Mostly uses on projects sites for open air blasting or blasting rooms. Compressed air is used for operation of this equipment. Equipment can be supplied with manual operation as well and auto automatic control systems.

Semi-automatic shot blasting equipment’s are booth type machines where in the operator can walk into the booth and carry out the shot blasting as per requirement. Advantage of this system is that it can accommodate variety of jobs. This is batch type Machine where the job can be conveyed into the booth by trolley, crane, monorail, or by hand. In this machine shot blasting done manually but recovery, recycling, dust collection etc. are all automatic processes. Machine can also be designed with complete auto recovery as well as semi-automatic recovery system.